Environmental regulations are getting stricter. The gas & oil and desalination industries will need to adopt more aggressive treatment strategies for liquid waste. ZLD, while not a new concept, isn’t used as a standard method due to the high capital and operating costs. The ADSS could be integrated into a ZLD plant at a reduced capital cost compared to the thermal technologies, which would be replaced. And, as the system efficiency is higher, the operating cost would be lower as well.

Zero Liquid Discharge

Environmental regulations are getting stricter. The gas & oil and desalination industries will need to adopt more aggressive treatment strategies for liquid waste. ZLD, while not a new concept, isn’t used as a standard method due to the high capital and operating costs. The ADSS could be integrated into a ZLD plant at a reduced capital cost compared to the thermal technologies, which would be replaced. And, as the system efficiency is higher, the operating cost would be lower as well.

Zero Liquid Discharge

Environmental regulations are getting stricter. The gas & oil and desalination industries will need to adopt more aggressive treatment strategies for liquid waste. ZLD, while not a new concept, isn’t used as a standard method due to the high capital and operating costs. The ADSS could be integrated into a ZLD plant at a reduced capital cost compared to the thermal technologies, which would be replaced. And, as the system efficiency is higher, the operating cost would be lower as well.

Air-Driven Separation System

( ADSS)

The ADSS can treat water with high TDS content and yield effluent that is highly viscous. This would make it ideal as both a pretreatment and first-stage concentration process application in a ZLD plant, significantly reducing the overall system complexity

Process Cost

of Water per M3

Process Cost

of Water per M3

A major difference between using the much less complex ADSS and traditional thermal desalination processes is the relatively lower specific energy consumption, which has been demonstrated in seawater purification by this process. These advantages would result in a much more cost-efficient ZLD plant, with potentially vast markets in the industrial wastewater and desalination industries.

A major difference between using the much less complex ADSS and traditional thermal desalination processes is the relatively lower specific energy consumption, which has been demonstrated in seawater purification by this process. These advantages would result in a much more cost-efficient ZLD plant, with potentially vast markets in the industrial wastewater and desalination industries.

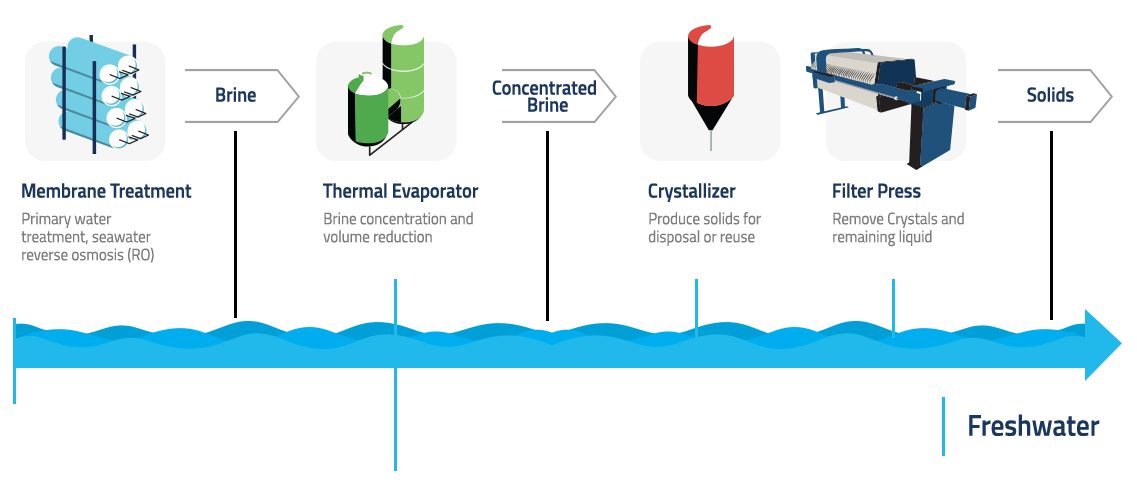

SWRO Brine Concentration

There is a need for a ZLD solution to specifically address brine disposal in the desalination industry. Currently, most SWRO plants around the globe discharge billions of cubic meters of high-salinity brine, resulting from the membrane process, directly into the ocean. Stricter environmental regulations coupled with the escalating costs of constructing and maintaining brine outfall systems are making this traditional method less attractive both technically and economically. In fact, several GCC countries are forming a mandate to end brine disposal in the Arabian Gulf. The GCC represents 55-60% of the global capacity for desalination.

SWRO Brine Concentration

There is a need for a ZLD solution to specifically address brine disposal in the desalination industry. Currently, most SWRO plants around the globe discharge billions of cubic meters of high-salinity brine, resulting from the membrane process, directly into the ocean. Stricter environmental regulations coupled with the escalating costs of constructing and maintaining brine outfall systems are making this traditional method less attractive both technically and economically. In fact, several GCC countries are forming a mandate to end brine disposal in the Arabian Gulf. The GCC represents 55-60% of the global capacity for desalination.

SWRO Brine Concentration

There is a need for a ZLD solution to specifically address brine disposal in the desalination industry. Currently, most SWRO plants around the globe discharge billions of cubic meters of high-salinity brine, resulting from the membrane process, directly into the ocean. Stricter environmental regulations coupled with the escalating costs of constructing and maintaining brine outfall systems are making this traditional method less attractive both technically and economically. In fact, several GCC countries are forming a mandate to end brine disposal in the Arabian Gulf. The GCC represents 55-60% of the global capacity for desalination.