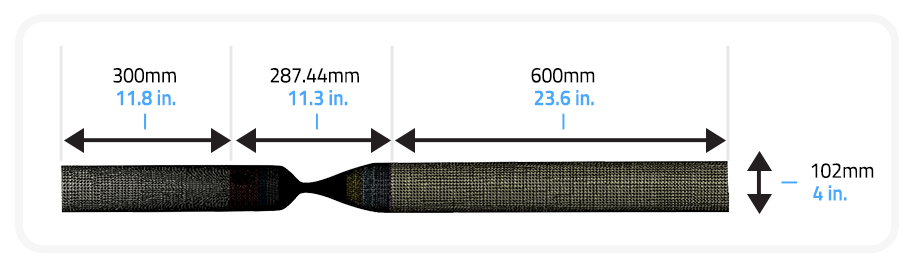

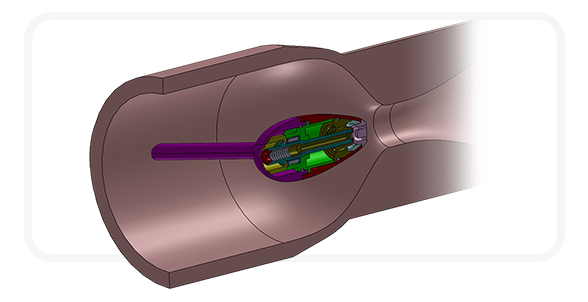

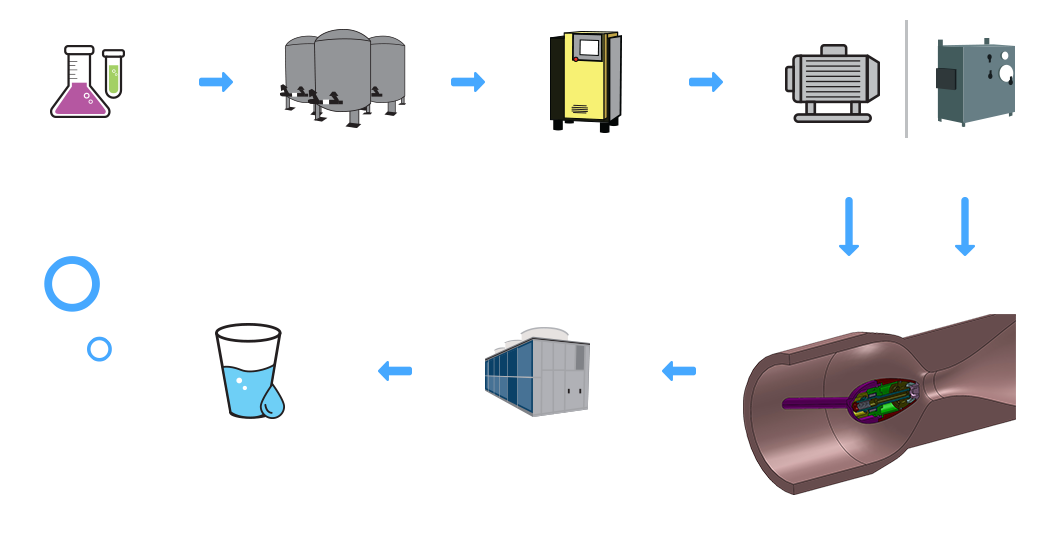

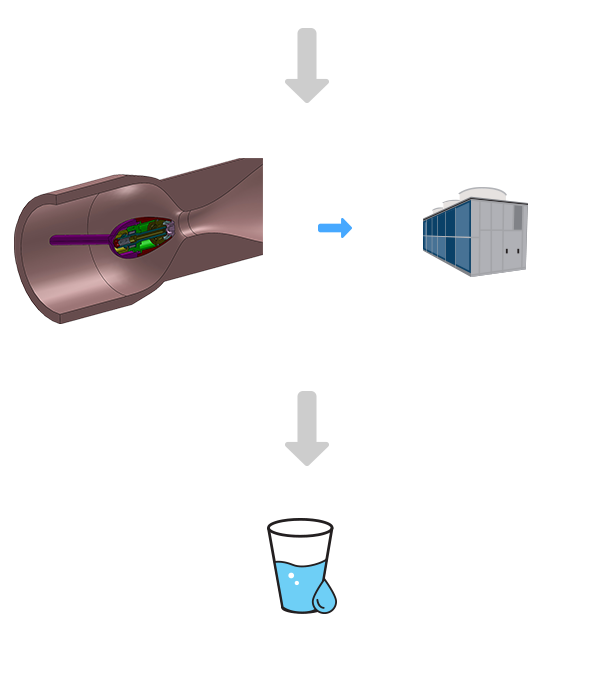

The MPA integrates well into the ADSS. The compact, modular design allows for either scalable on-site or fixed plant installations. Like reverse osmosis, output volume is based on unit size and quantity. Therefore, a mobile application may require only 10 ADSS units to achieve the desired capacity while a commercial desalination plant would utilize several thousand. The diagram below is for illustrative purposes and shows the central portion of the ADSS scaled for an on-site application.

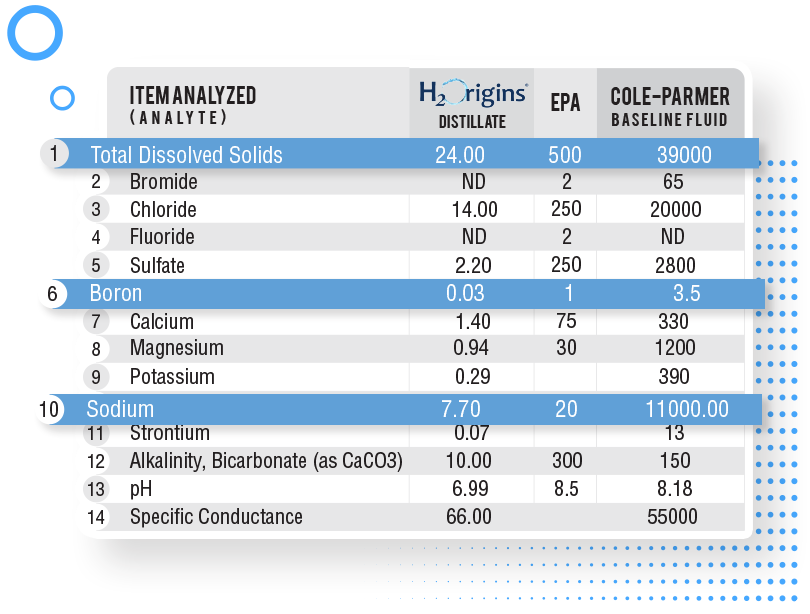

ADSS Desalination Test Results

A fluid known as synthetic seawater was processed with the ADSS. The composition of the baseline solution is shown in the right column while the processed water results are shown to the left. The EPA allowances are shown in the center. The ADSS exceeds the water purity standards in every category. Total dissolved solids were reduced from 39,000 mg/L to 24 mg/L and sodium from 11,000 mg/L to 7.7 mg/L. Of particular note is Boron, a very difficult mineral to extract from water. The ADSS was able to reduce the level of Boron from 3.5 mg/L to 0.03 mg/L.

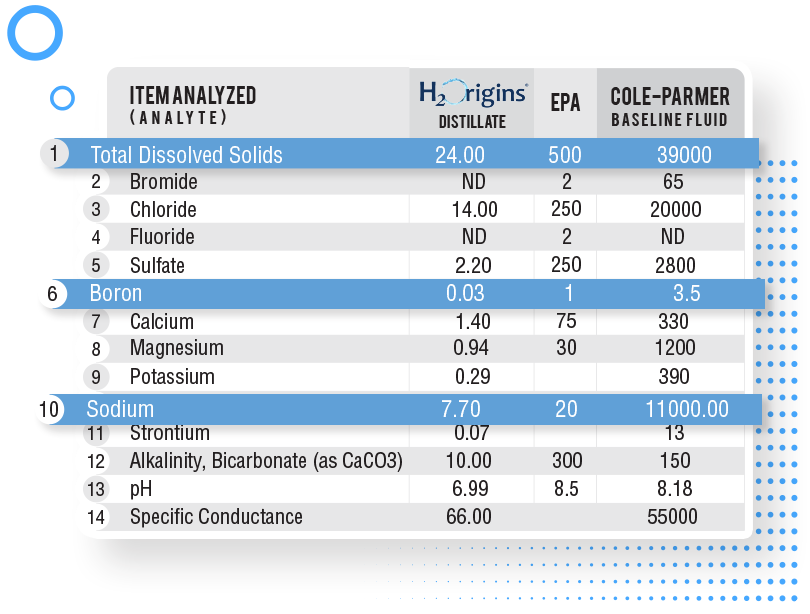

ADSS Desalination Test Results

A fluid known as synthetic seawater was processed with the ADSS. The composition of the baseline solution is shown in the right column while the processed water results are shown to the left. The EPA allowances are shown in the center. The ADSS exceeds the water purity standards in every category. Total dissolved solids were reduced from 39,000 mg/L to 24 mg/L and sodium from 11,000 mg/L to 7.7 mg/L. Of particular note is Boron, a very difficult mineral to extract from water. The ADSS was able to reduce the level of Boron from 3.5 mg/L to 0.03 mg/L.

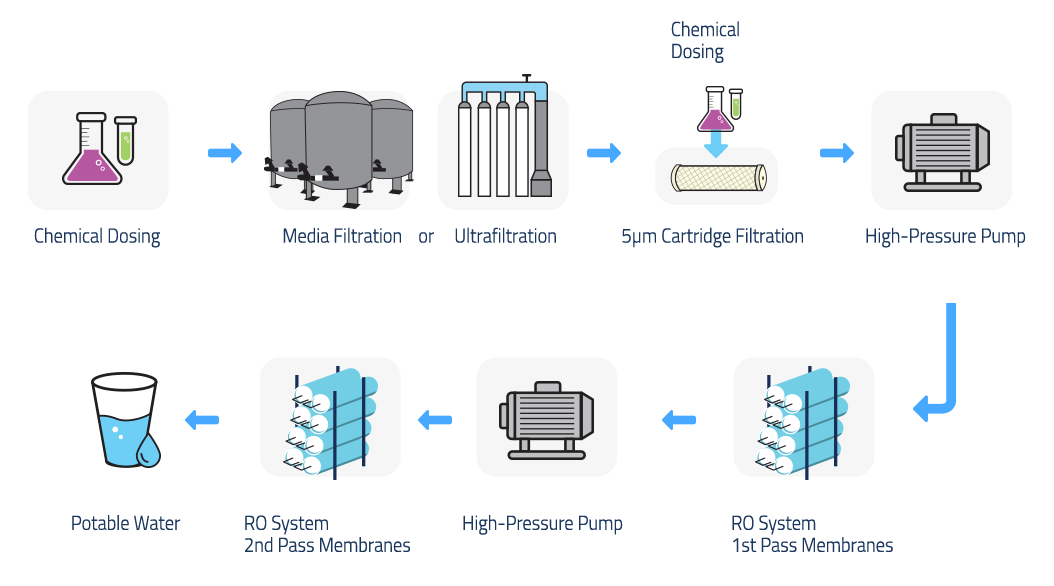

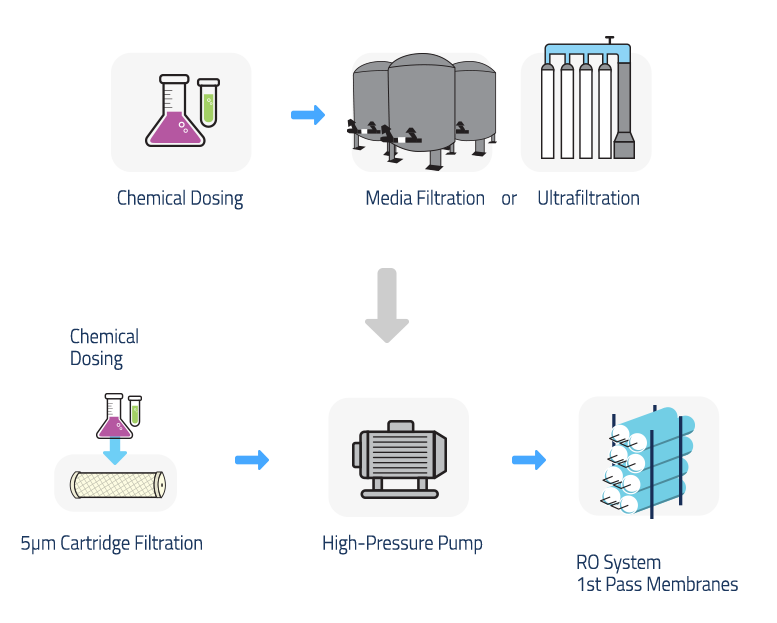

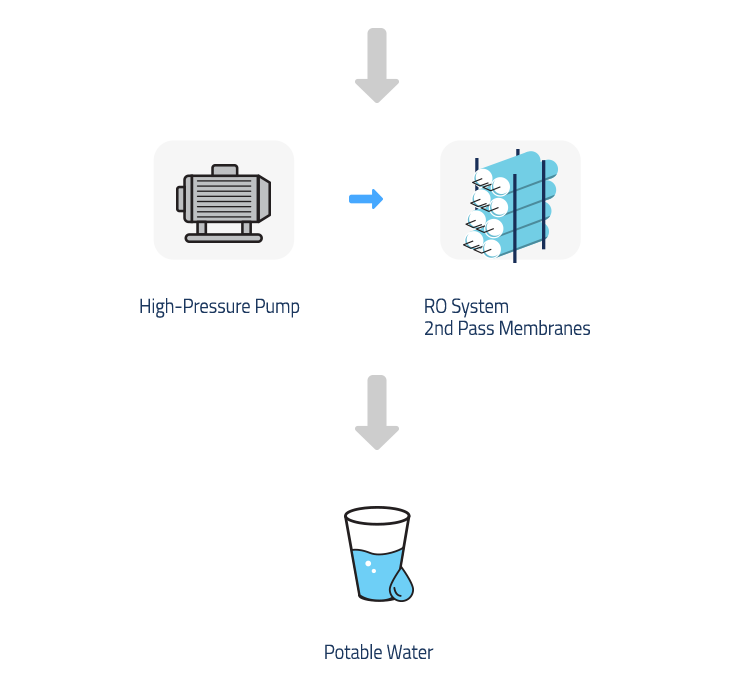

Legacy SWRO Process

High-preasure pumps, largest recurring cost

Recurring cost

With the exception of chlorine, the chemicals used to dose seawater facilitate membrane longevity. They do not aid in removing salt. While two stages of membranes comprised of sub-micron pores are utilized to desalinate the seawater, another membrane-based technology with small-micron pores is often used in the pre-filtration process. Powering the high-pressure pumps represents the largest recurring cost in an SWRO plant.

Legacy SWRO Process

High-preasure pumps, largest recurring cost

Recurring cost

With the exception of chlorine, the chemicals used to dose seawater facilitate membrane longevity. They do not aid in removing salt. While two stages of membranes comprised of sub-micron pores are utilized to desalinate the seawater, another membrane-based technology with small-micron pores is often used in the pre-filtration process. Powering the high-pressure pumps represents the largest recurring cost in an SWRO plant.

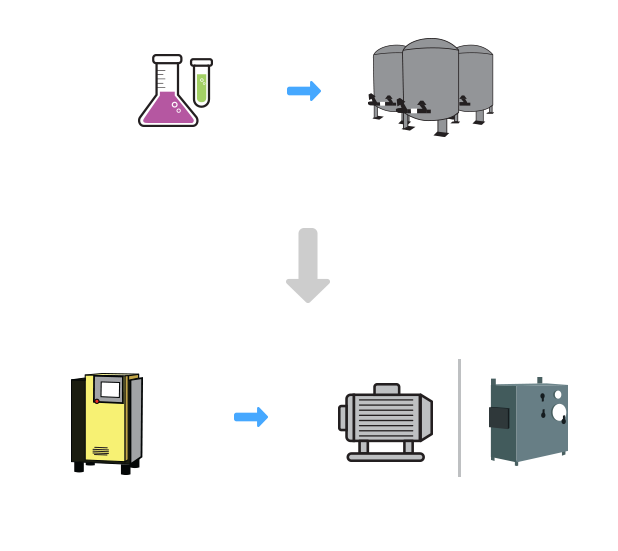

ADSS Purification Process

lower CAPEX and significantly reduced daily operating costs.

Reduced daily operating cost

In a ADSS plant, chemical dosing would be reduced and ultrafiltration systems would not be necessary. As this is a low-pressure system, high-pressure pumps are not required either. The low-pressure pumps together with the air compressors used in ADSS will consume less energy than the high-pressure pumps used in SWRO. In addition, the small-particle atomization produced by the ADSS creates the optimal environment for ozone use in the disinfection process.

ADSS Purification Process

lower CAPEX and significantly reduced daily operating costs.

Reduced daily operating cost

In a ADSS plant, chemical dosing would be reduced and ultrafiltration systems would not be necessary. As this is a low-pressure system, high-pressure pumps are not required either. The low-pressure pumps together with the air compressors used in ADSS will consume less energy than the high-pressure pumps used in SWRO. In addition, the small-particle atomization produced by the ADSS creates the optimal environment for ozone use in the disinfection process.