V-STAX has developed a core nanogasification technology capable of reducing any liquid into specific small micron (μm) particles in a homogenized mist. Unlike other small particle technologies, high-pressures, exotic materials and complex machining are not required. Any chemical reaction will benefit from the high surface to volume ratio that results from the small particle mists. The Company is currently working on three applications utilizing the technology.

Nanogasification Technology

V-STAX has developed a core nanogasification technology capable of reducing any liquid into specific small micron (μm) particles in a homogenized mist. Unlike other small particle technologies, high-pressures, exotic materials and complex machining are not required. Any chemical reaction will benefit from the high surface to volume ratio that results from the small particle mists. The Company is currently working on three applications utilizing the technology.

Particle size

High-speed photography clearly shows (50,000 frames per second) the dramatic difference in particle size and shape of plumes between a modern PFI injector and the Enginetics/V-STAX Multi Physics Atomizer (MPA).

Particle size

High-speed photography clearly shows (50,000 frames per second) the dramatic difference in particle size and shape of plumes between a modern PFI injector and the Enginetics/V-STAX Multi Physics Atomizer (MPA).

Particle size

High-speed photography clearly shows (50,000 frames per second) the dramatic difference in particle size and shape of plumes between a modern PFI injector and the Enginetics/V-STAX Multi Physics Atomizer (MPA).

A Large volume of liquid

into a small micron band

ZLD

The ADSS can treat water with high TDS content and yield effluent that is highly viscous.

Fracking

The ADSS would be most effective as a core technology in an integrated on-site treatment system for produced water

Desalination

The MPA integrates well into the Gen 2 ADSS. The compact, modular design allows for a scalable on-site wastewater system to be realized

A Large volume of liquid

into a small micron band

ZLD

The ADSS can treat water with high TDS content and yield effluent that is highly viscous.

Fracking

The ADSS would be most effective as a core technology in an integrated on-site treatment system for produced water

Desalination

The MPA integrates well into the Gen 2 ADSS. The compact, modular design allows for a scalable on-site wastewater system to be realized

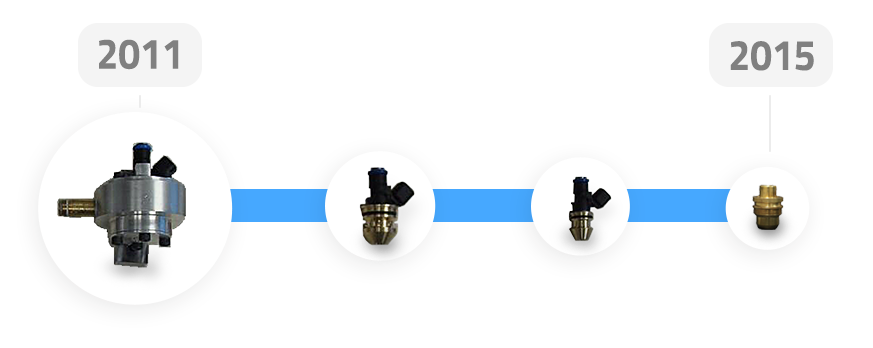

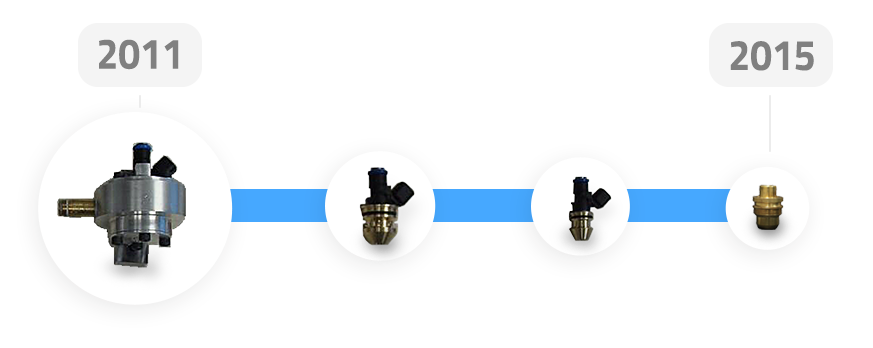

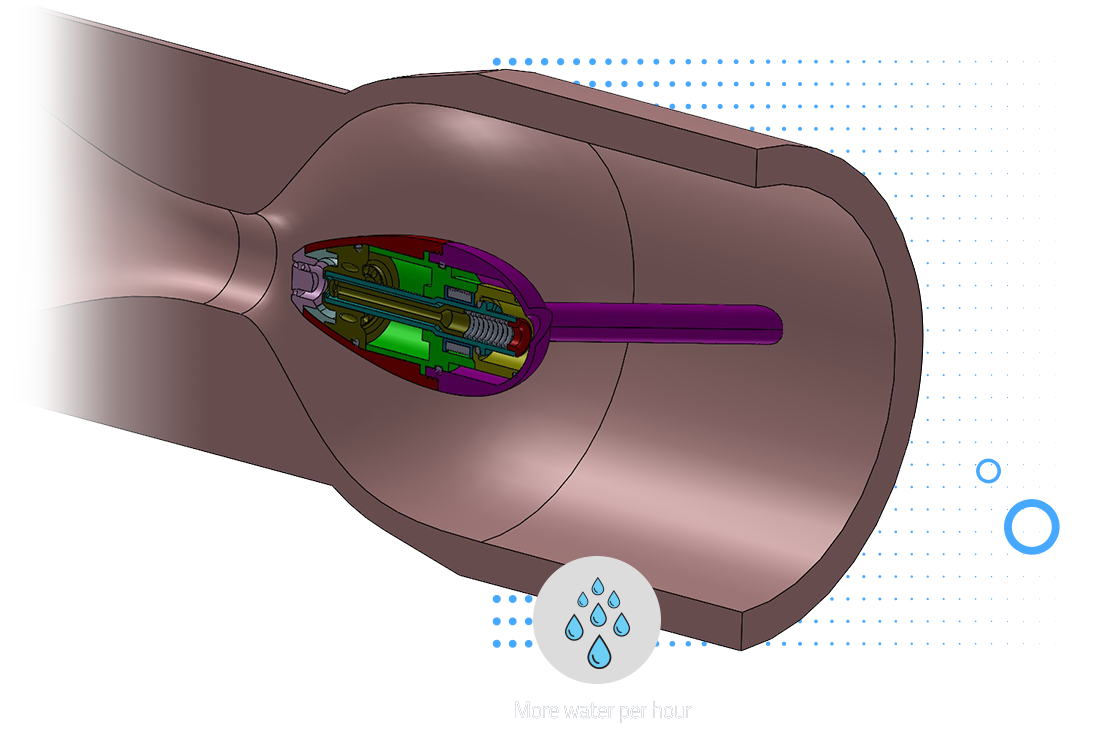

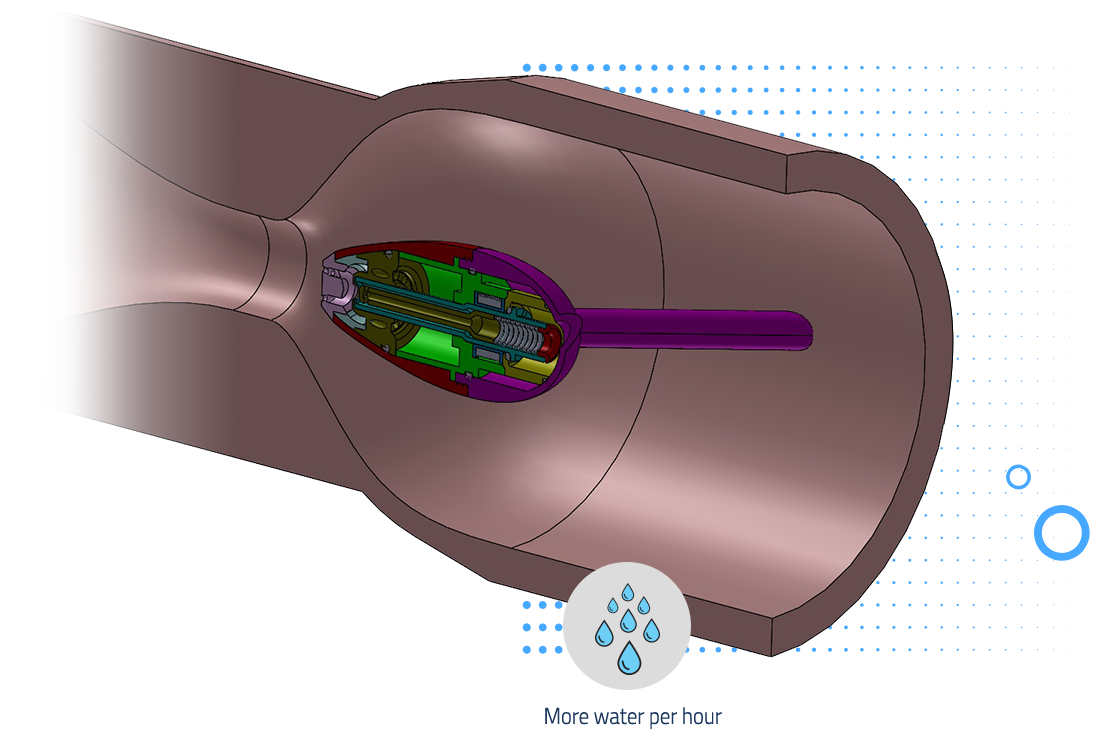

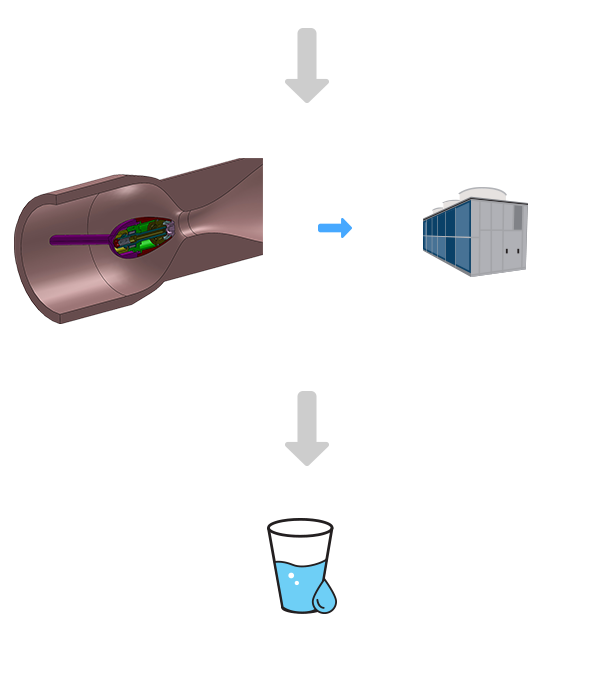

Multi Physics Atomizer

The Multi Physics Atomizer (MPA) is capable of processing a large volume of liquid into a small micron band. This nozzle is integral to the Generation 2 Air-Driven Separation System (ADSS). It is very robust and unlike RO membranes does not require submicron perforations. In fact, the smallest perforations in the MPA are over a thousands times greater in diameter than the largest pores in an RO membrane. And, as the ADSS is air-assisted, the MPA can be purged occasionally with a brief air-only event to prevent fouling.

Multi Physics Atomizer

The Multi Physics Atomizer (MPA) is capable of processing a large volume of liquid into a small micron band. This nozzle is integral to the Generation 2 Air-Driven Separation System (ADSS). It is very robust and unlike RO membranes does not require submicron perforations. In fact, the smallest perforations in the MPA are over a thousands times greater in diameter than the largest pores in an RO membrane. And, as the ADSS is air-assisted, the MPA can be purged occasionally with a brief air-only event to prevent fouling.

Reduced or No Pretreatment

Reduced Chemicals

Substantially Reduced Energy Consumption

Substantially Reduced Total Cost of Water

Modular Design and Layout

Reduced or No Pretreatment

Reduced Chemicals

Substantially Reduced Energy Consumption

Substantially Reduced Total Cost of Water

Modular Design and Layout

Generation 2 ADSS

The Gen 2 ADSS will be powered by the MPA. The system is mechanically simpler than the Gen 1 design and capable of processing considerably more water per hour.

Generation 2 ADSS

The Gen 2 ADSS will be powered by the MPA. The system is mechanically simpler than the Gen 1 design and capable of processing considerably more water per hour.

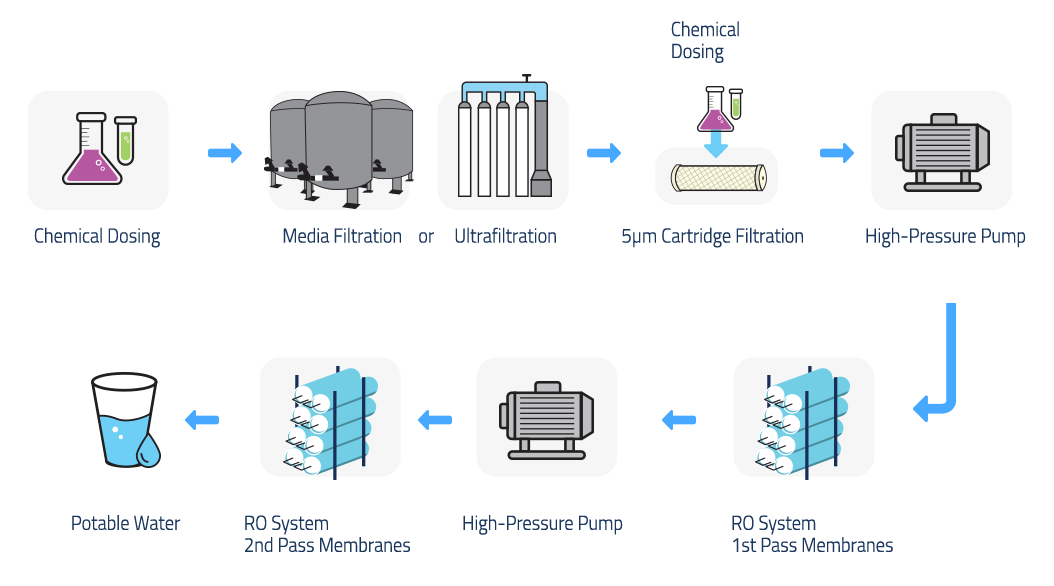

Legacy SWRO Process

High-preasure pumps, largest recurring cost

Recurring cost

With the exception of chlorine, the chemicals used to dose seawater facilitate membrane longevity. They do not aid in removing salt. While two stages of membranes comprised of sub-micron pores are utilized to desalinate the seawater, another membrane-based technology with small-micron pores is often used in the pre-filtration process. Powering the high-pressure pumps represents the largest recurring cost in an SWRO plant.

Legacy SWRO Process

High-preasure pumps, largest recurring cost

Recurring cost

With the exception of chlorine, the chemicals used to dose seawater facilitate membrane longevity. They do not aid in removing salt. While two stages of membranes comprised of sub-micron pores are utilized to desalinate the seawater, another membrane-based technology with small-micron pores is often used in the pre-filtration process. Powering the high-pressure pumps represents the largest recurring cost in an SWRO plant.

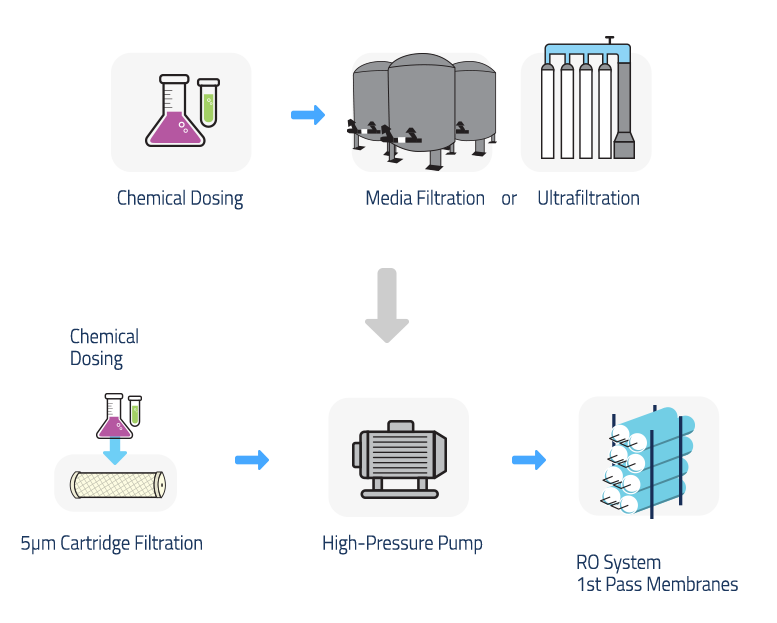

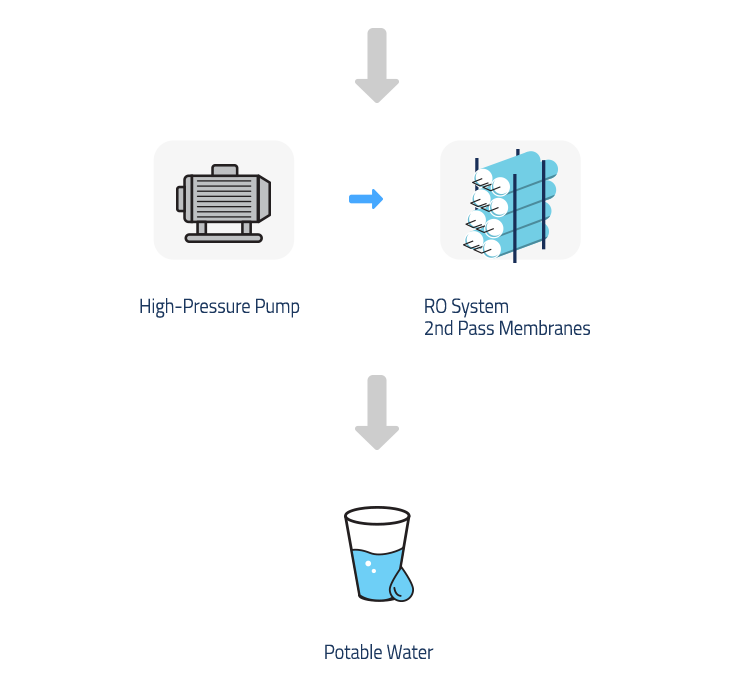

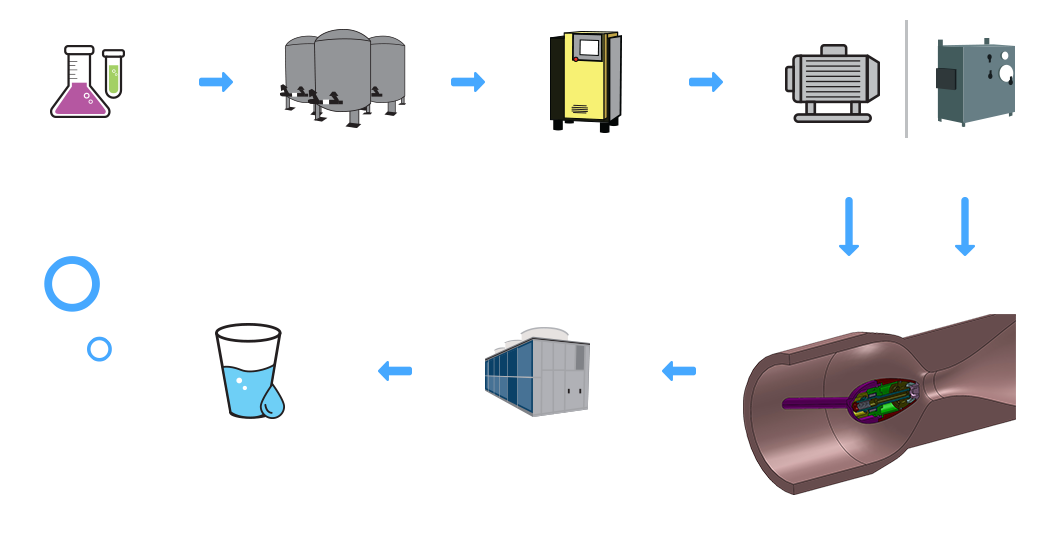

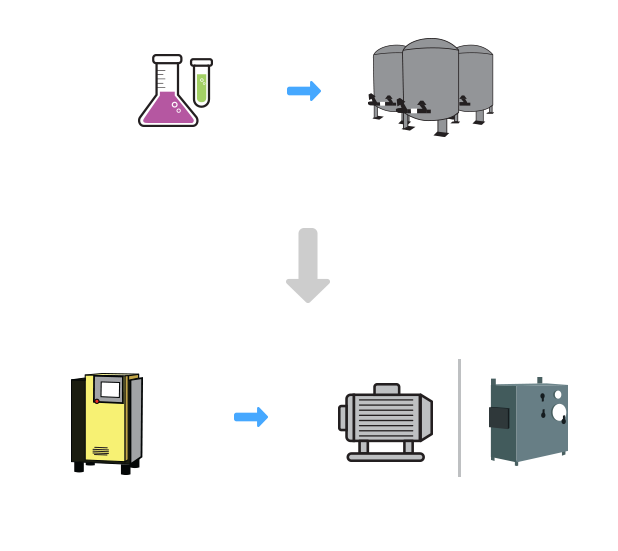

ADSS Purification Process

lower CAPEX and significantly reduced daily operating costs.

Reduced daily operating cost

In a ADSS plant, chemical dosing would be reduced and ultrafiltration systems would not be necessary. As this is a low-pressure system, high-pressure pumps are not required either. The low-pressure pumps together with the air compressors used in ADSS will consume less energy than the high-pressure pumps used in SWRO. In addition, the small-particle atomization produced by the ADSS creates the optimal environment for ozone use in the disinfection process.

ADSS Purification Process

lower CAPEX and significantly reduced daily operating costs.

Reduced daily operating cost

In a ADSS plant, chemical dosing would be reduced and ultrafiltration systems would not be necessary. As this is a low-pressure system, high-pressure pumps are not required either. The low-pressure pumps together with the air compressors used in ADSS will consume less energy than the high-pressure pumps used in SWRO. In addition, the small-particle atomization produced by the ADSS creates the optimal environment for ozone use in the disinfection process.

Patents

The STAX Companies have been issued 23 U.S. patents to date, with the most recent patent issuing on January 25, 2022. In addition to U.S. patents, the Company has numerous international patents issued and several patent applications pending in the U.S. and foreign countries.