Advancements in hydraulic fracturing (“fracking”) have allowed US energy companies to access natural gas and oil trapped in shale. Production from this sector is the main reason the US is now an energy exporter. While the technologies associated with extraction have evolved over the years the methods for water treatment have remained the same. And with environmental regulations getting stricter, new options will be required. The ADSS will provide a robust solution for managing wastewater heavily ladened with chemicals, oil and sand

Fracking

Advancements in hydraulic fracturing (“fracking”) have allowed US energy companies to access natural gas and oil trapped in shale. Production from this sector is the main reason the US is now an energy exporter. While the technologies associated with extraction have evolved over the years the methods for water treatment have remained the same. And with environmental regulations getting stricter, new options will be required. The ADSS will provide a robust solution for managing wastewater heavily ladened with chemicals, oil and sand

U.S. Shale Gas Industry

The U.S. shale gas industry spends billions of dollars a year treating wastewater. In addition, billions more are spent to transport the wastewater between the fracking sites and water treatment facilities. The ADSS can form the foundation of an efficient industrial wastewater treatment system less prone to fowling than current alternatives. And, as the technology is modular, systems can be scaled for treatment on-site to reduce the number of barrels of waste that must be transported.

Annual Market for Wastewater Treatment

Annual Market for Wastewater Transportation

U.S. Shale Gas Industry

The U.S. shale gas industry spends billions of dollars a year treating wastewater. In addition, billions more are spent to transport the wastewater between the fracking sites and water treatment facilities. The ADSS can form the foundation of an efficient industrial wastewater treatment system less prone to fowling than current alternatives. And, as the technology is modular, systems can be scaled for treatment on-site to reduce the number of barrels of waste that must be transported.

Annual Market for Wastewater Treatment

Annual Market for Wastewater Transportation

Billions per year

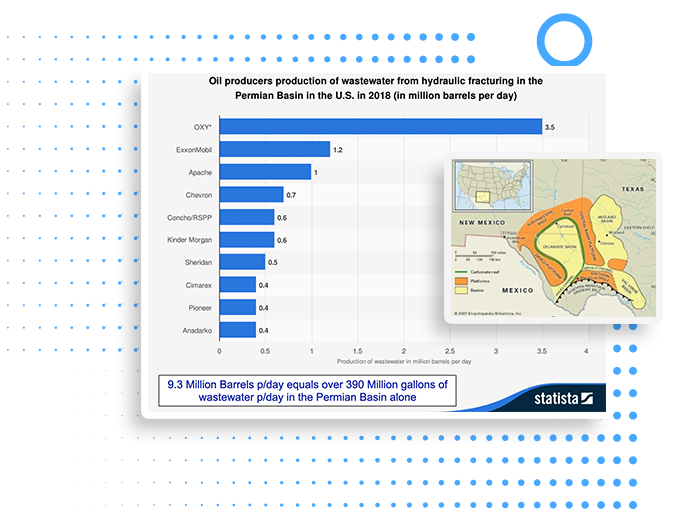

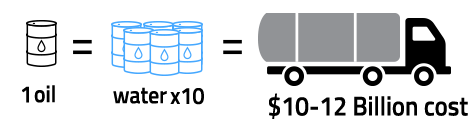

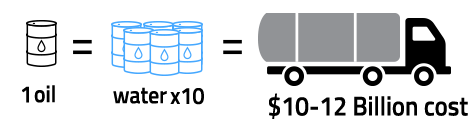

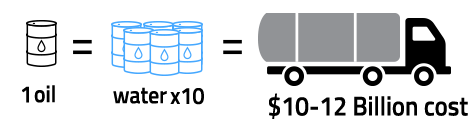

For every barrel of oil extracted through fracking, 8-10 barrels of water are produced. The water contains various quantities of fracking fluids, oil, heavy metals, chloride and possibly radioactive compounds. Produced water is not suitable even for reuse without treatment. Currently, gas and oil companies treat only a small portion of produced water for reuse. The rest is disposed of in static ponds or through deep well injection. However, the transportation costs alone to haul the wastewater to a disposal site in the U.S. range from $3 to $7 per barrel. This translates to between $10-$12 billion a year.

Billions per year

For every barrel of oil extracted through fracking, 8-10 barrels of water are produced. The water contains various quantities of fracking fluids, oil, heavy metals, chloride and possibly radioactive compounds. Produced water is not suitable even for reuse without treatment. Currently, gas and oil companies treat only a small portion of produced water for reuse. The rest is disposed of in static ponds or through deep well injection. However, the transportation costs alone to haul the wastewater to a disposal site in the U.S. range from $3 to $7 per barrel. This translates to between $10-$12 billion a year.

Billions per year

For every barrel of oil extracted through fracking, 8-10 barrels of water are produced. The water contains various quantities of fracking fluids, oil, heavy metals, chloride and possibly radioactive compounds. Produced water is not suitable even for reuse without treatment. Currently, gas and oil companies treat only a small portion of produced water for reuse. The rest is disposed of in static ponds or through deep well injection. However, the transportation costs alone to haul the wastewater to a disposal site in the U.S. range from $3 to $7 per barrel. This translates to between $10-$12 billion a year.

Total dissolved solids (TDS)

The ADSS would be most effective as a core technology in an integrated on-site treatment system for produced water. As the ADSS is not a small-pore technology like RO or graphene, fluids with high concentrations of TDS can be processed without fouling. In addition, the flow of produced water can be interrupted for a few tenths of a second, allowing for periodic air purges to keep the system deposit-free.

Growing Need

The need for water treatment in the oil/gas sector grows dramatically each year. In 2016, there were 1.7 million active oil and gas wells in the USA. In just one calendar year between 2017 and 2018, over 94,000 new wells were drilled. When completed each well will produce up to 378 m3 of wastewater per day.

U.S. Shale Gas Industry

The U.S. shale gas industry spends billions of dollars a year treating wastewater. In addition, billions more are spent to transport the wastewater between the fracking sites and water treatment facilities. The ADSS can form the foundation of an efficient industrial wastewater treatment system less prone to fowling than current alternatives. And, as the technology is modular, systems can be scaled for treatment on-site to reduce the number of barrels of waste that must be transported.

There are over 1.7 Million active oil and gas wells in the US.